Focus op

Power Quality

Would you like more information?

Olaf Moens

Managing Director

Installations break down, lamps start blinking or need to be replaced constantly, installations behave unpredictably or make noises. This can all be the result of poor Power Quality; in other words, the quality of the power grid, the voltage and current quality.

Poor Power Quality can have several causes. The installation of new modern electrical equipment, solar panels or LED lighting are the most common causes of poor Power Quality. Due to all kinds of new developments, the electricity grid is loaded to such an extent that the quality of the energy required is not optimal.

Poor Power Quality of your energy supply threatens the continuity, effectiveness, but also the safety of your electrical appliances or installations. It increases the likelihood of malfunctions and ultimately damage, which in turn leads to high maintenance or replacement costs. The consequences of poor electricity quality may be the ignition of cables or the rapid ageing of installations or equipment.

Improving the Power Quality not only increases operational safety and security, but in most cases also results in cost savings and more sustainable energy consumption.

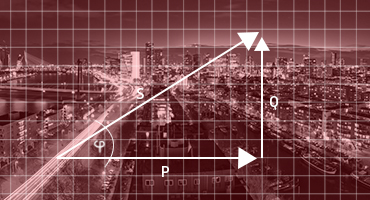

The Power Quality can be improved in 3 different ways:

Reactive current compensation |

Harmonic filtering |

Voltage stabilisation |

|

|

|

| Het compenseren van blindvermogen door de installatie van vaste dan wel geregelde condensatoren. | Het verlagen van harmonische vervuiling door de installatie van actieve/passieve harmonische filter. | Het voorkomen dan wel verminderen van spanningsveranderingen (flicker, dips, spanningsasymetrie). |

How do we solve Power Quality problems?

|

MeasurementsIt is not easy to link systems to the concept of Power Quality. A simple example: ‘ A fluorescent light source that malfunctions several times is usually simply replaced. Because the fluorescent light source has already malfunctioned several times, it may be due to poor Power Quality.’ We can carry out an inventory and analysis of such undetected problems. We have calibrated measuring equipment for this purpose. This measurement equipment allows us to identify the causes. This will also identify causes unrelated to your electrical system.

|

|

AdviceFinding the cause is one thing, but making an analysis based on the measured data and offering a solution is the next step. Based on our many years of experience and our knowledge, we are able to define the right solution for you. Not only the technical aspects but also the necessary business considerations are taken into account. |

|

Supply & installationBatenburg Energietechniek is unique in the sense that we don’t stop at just giving advice. Where necessary, we will follow up the advice by supplying and installing the solution(s). This includes reactive current compensation by means of capacitor banks and/or batteries. We will then demonstrate that your Power Quality has improved by performing a second data analysis, making the circle complete.

|

|

Service, management & maintenanceMaintaining optimum Power Quality requires monitoring and maintaining the specific installation. As the supplier, no one is more familiar with the components than we are. Our fully equipped service teams periodically perform the necessary preventive actions and are deployed in the event of emergencies.

|